Introduction: Understanding the Critical Components of Oil and Gas Wells

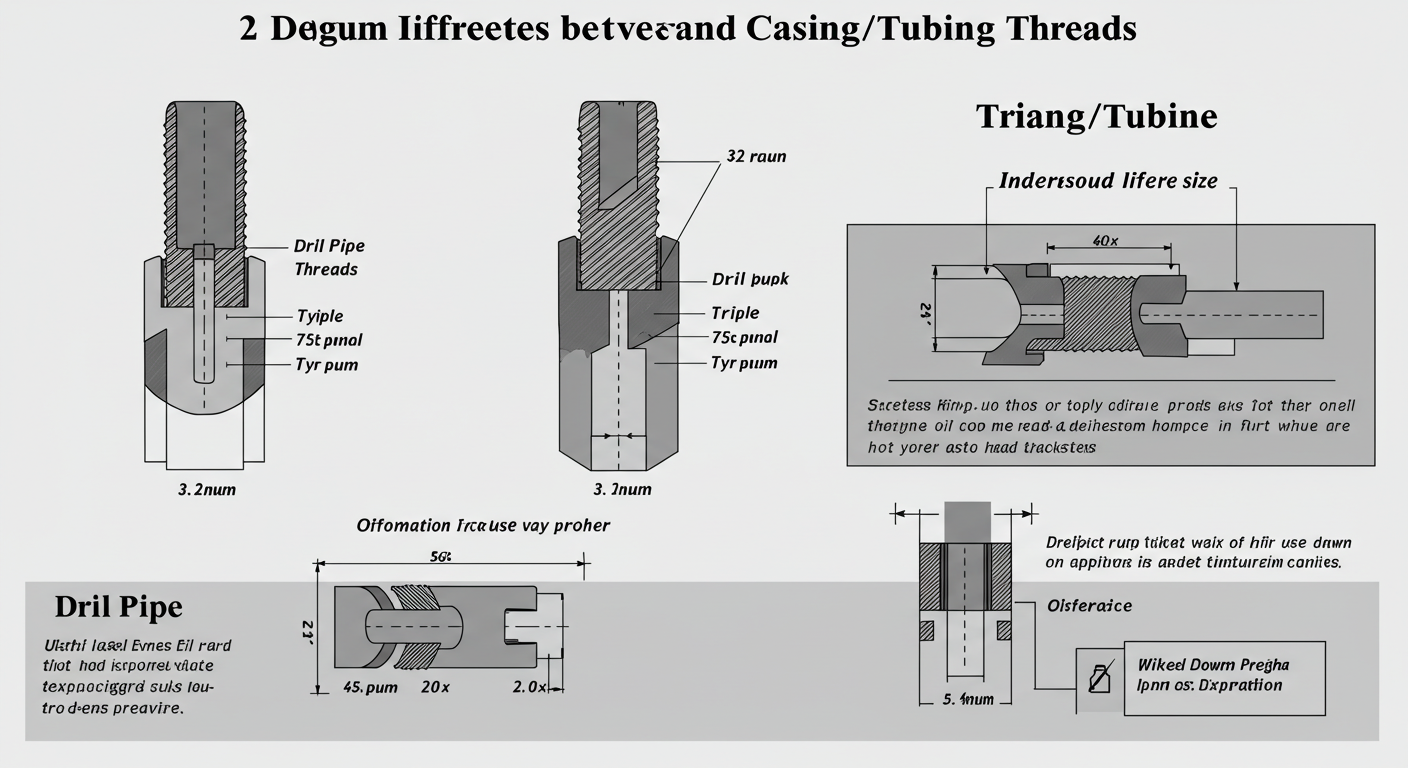

In the high-stakes world of oil and gas extraction, three critical components form the backbone of any successful drilling operation: drill pipe, casing, and tubing. While these cylindrical metal components might look similar to the untrained eye, their thread designs, specifications, and functions differ significantly – and getting these details right can mean the difference between a productive well and a costly failure.

This comprehensive guide explores the key differences between drill pipe threads and casing/tubing threads, helping industry professionals make informed decisions when selecting components for their operations.

The Fundamental Trio: Drill Pipe, Casing, and Tubing Explained

Before diving into thread specifications, let’s clarify what each component does in the drilling process:

Drill Pipe: The Dynamic Connector

Drill pipe serves as the crucial link between surface drilling equipment and the downhole drill bit. This workhouse component:

- Transmits rotational force from the surface to the drill bit

- Circulates drilling fluid to and from the bottom of the well

- Must withstand extreme torque, tension, and pressure variations

- Requires frequent connection/disconnection during drilling operations

Casing: The Protective Shell

Once a section of wellbore is drilled, casing is installed to:

- Prevent wellbore collapse

- Isolate different pressure zones and formations

- Protect freshwater aquifers from contamination

- Provide structural integrity for the entire well system

- Withstand long-term exposure to wellbore conditions

Tubing: The Production Conduit

After the well is drilled and cased, tubing becomes the primary conduit for:

- Transporting oil and gas from the reservoir to the surface

- Facilitating well interventions and workover operations

- Isolating production zones within the well

- Optimizing flow characteristics for hydrocarbons

Drill Pipe Threads: Engineered for Dynamic Performance

Key Characteristics of Drill Pipe Threads

Drill pipe threads are specifically designed for the unique demands of drilling operations:

| Characteristic | Description |

| Thread Type | Predominantly tapered for quick and secure connection |

| Material | High-strength steel to withstand extreme temperatures and pressures |

| Connection Method | Pin and box design for reliability and repeated make/break cycles |

| Sealing Capability | Metal-to-metal seals to prevent fluid loss during circulation |

Design and Functionality Features

The engineering behind drill pipe threads reflects their demanding operational environment:

- Specialized Geometry: Load-distributing profiles to minimize stress concentration points

- High Torque Capacity: Designed to transmit significant rotational force without failure

- Wear Resistance: Engineered to maintain integrity through numerous connection cycles

- API Standardization: Manufactured to strict API specifications for universal compatibility

Casing and Tubing Threads: Built for Long-Term Reliability

Differentiating Casing from Tubing Threads

While both are critical to well integrity, casing and tubing threads have distinct characteristics:

| Feature | Casing | Tubing |

| Diameter | Larger (typically 7″ and above) | Smaller (typically 2.37″ to 4.5″) |

| Primary Purpose | Wellbore stabilization | Hydrocarbon transportation |

| Installation Depth | From surface to target depth | Inside the casing string |

| Thread Design | Robust threads for structural integrity | Precision threads for leak-free connections |

These fundamental differences drive significant variations in thread design, with each optimized for its specific function and operating conditions.

Technical Specifications Under API Standards

The American Petroleum Institute (API) establishes rigorous standards for both casing and tubing threads:

| Specification | Casing Thread Standard | Tubing Thread Standard |

| API Reference | API 5CT | API 5CT |

| Common Thread Types | BTC (Buttress), LTC (Long Thread Coupling), STC (Short Thread Coupling) | EUE (External Upset End), NUE (Non-Upset End) |

| Tensile Strength | Varies by grade and size | Varies by grade and size |

| Weight Range | 20-50+ lb/ft | 5-20+ lb/ft |

| Yield Strength | 35,000-80,000 psi | 30,000-60,000 psi |

API Specifications: Setting the Industry Standard

API Casing Specifications

API specifications ensure casing meets stringent quality and performance requirements:

| API Casing Grade | Code | Minimum Yield Strength (psi) | Typical Weight (lbs/ft) |

| API 5CT H40 | H40 | 40,000 | 40 |

| API 5CT J55 | J55 | 55,000 | 65 |

| API 5CT K55 | K55 | 55,000 | 90 |

| API 5CT N80 | N80 | 80,000 | 95 |

| API 5CT L80 | L80 | 80,000 | 105 |

| API 5CT P110 | P110 | 110,000 | 140 |

Each grade is designed for specific wellbore conditions, with higher grades generally suitable for more demanding environments.

API Tubing Specifications

Similarly, API tubing specifications establish clear performance benchmarks:

| API Tubing Grade | Code | Minimum Yield Strength (psi) | Typical Weight (lbs/ft) |

| API 5CT J55 | J55 | 55,000 | 20 |

| API 5CT K55 | K55 | 55,000 | 25 |

| API 5CT N80 | N80 | 80,000 | 30 |

| API 5CT L80 | L80 | 80,000 | 35 |

| API 5CT P110 | P110 | 110,000 | 40 |

Understanding these specifications is essential for selecting tubing that delivers reliable performance under specific well conditions.

Head-to-Head Comparison: Drill Pipe vs. Casing/Tubing Threads

Thread Design Variations

The design differences between drill pipe and casing/tubing threads reflect their distinct operational requirements:

| Design Element | Drill Pipe Threads | Casing Threads | Tubing Threads |

| Thread Type | API or Unified | Buttress or API Round | API Round or ANSI |

| Pitch | Generally finer | Coarser for pressure integrity | Medium to fine |

| Profile | Primarily tapered | Straight or slightly tapered | Round or tapered |

| Size Range | 2⅜” to 6⅝” | 4″ to 20″ | 1¼” to 4″ |

| Connection Style | Flush joint or upset | Regular or heavy-duty | Integral joint or coupling |

Strength and Durability Factors

Performance characteristics vary significantly between thread types:

| Performance Factor | Drill Pipe Threads | Casing Threads | Tubing Threads |

| Tensile Strength | High | High to very high | Moderate to high |

| Yield Strength | High | High | Moderate to high |

| Corrosion Resistance | Moderate | High (grade-dependent) | Good to excellent |

| Fatigue Resistance | Very high | Moderate to high | Variable |

| Optimal Application | Drilling operations | Wellbore stabilization | Production flow |

These performance differences highlight why proper selection is critical for specific drilling and production objectives.

Choosing the Right Components: Key Selection Factors

Operational Requirements

The operational parameters of your project drive component selection:

| Operational Factor | Consideration Points |

| Well Depth | Deeper wells require higher-grade materials |

| Operating Pressure | Higher pressures demand greater thread integrity |

| Fluid Composition | Corrosive fluids need specialized thread materials |

Wellbore Conditions

The wellbore environment significantly impacts thread performance:

| Wellbore Condition | Recommended Thread/Material |

| High Temperature | High-strength, heat-resistant alloys |

| Corrosive Environment | Corrosion-resistant alloys with specialized coatings |

| Formation Instability | Heavy-wall, high-strength connections |

Equipment Compatibility

Thread selection must account for compatibility with existing equipment:

| Equipment Type | Compatible Threading Requirements |

| Rotary Drilling Systems | API regular and premium connections |

| Completion Systems | API casing and tubing threads |

| Wellhead Equipment | Specific connection types based on manufacturer |

Conclusion: Making Informed Selections for Optimal Performance

Understanding the critical differences between drill pipe threads and casing/tubing threads is essential for successful oil and gas operations. By considering the specific requirements of each component and selecting the appropriate API specifications, operators can ensure:

- Enhanced operational safety

- Improved well integrity

- Extended component lifespan

- Reduced maintenance costs

- Optimized production performance

Whether you’re drilling a new well or planning a workover operation, the right thread selection can significantly impact your project’s efficiency and profitability. By leveraging the information provided in this guide, you’ll be better equipped to make informed decisions that align with your operational objectives and wellbore conditions.